I saw Brad at the job site this afternoon. The crew from Jim Giancola Concrete was just finishing up -- picking up all the loose nails and scraps of wire on the floor of the basement with a magnet. They were also putting a ribbon of Greenstreak PVC Waterstop around the edge of the forms. This material will be embedded halfway in the structural slab and halfway in the middle of the basement walls. Yet another layer of waterproofing material for added redundancy.

Brad was waiting for John, the structural engineer from John Ou & Associates, to come and look over and sign off on the rebar work. John's only comment was to move a couple of the curved rebar pieces closer to the edge near the lightwell in the back left of the basement.

Dennis, the field foreman from Jim Giancola Concrete, estimates his crew put down about 10 tons of rebar for the structural slab! There are probably about six more tons of straight rebar sitting in the street. That rebar will be used in the foundation walls.

Brad will be meeting the plumber and the city inspector tomorrow morning. The plumber is going to put in some piping for the drains in each of the light wells. If the inspector signs off on all the work, then Brad will be pouring the structural slab at 8:00 AM on Wednesday.

Brad will let the concrete set for the rest of the week and through the weekend. Then Dennis will be back out next Monday to start building the forms for the walls.

Monday, July 31, 2006

Sunday, July 30, 2006

I stopped by the job site this morning and took a few pictures.

I stopped by the job site this morning and took a few pictures.It looks like the crew from Jim Giancola Concrete is almost finished constructing all the rebar. You can see there are two layers of steel down in the basement.

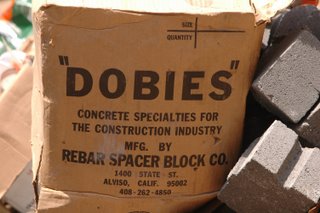

Those small concrete spacers between the rebar layers are called "Dobies."

Thursday, July 27, 2006

The crew from Jim Giancola Concrete continued their work on the rebar today. They're almost done with the first layer, and they just started the second layer.

The crew from Jim Giancola Concrete continued their work on the rebar today. They're almost done with the first layer, and they just started the second layer.Brad is going to check the sewer lines early next week. See that long pipe sticking straight up (on the left side of the second picture? That's for creating a ten-foot high column of water to pressure test the sewer lines.

Early next week Waterproofing Associates will bring out an inspector to check the installation of their materials. The city inspector will also be out to sign off before the concrete is poured.

Wednesday, July 26, 2006

Dennis and his crew from Jim Giancola Concrete continued their work laying out the rebar (that's Dennis on the left in the first picture). Because there's limited access to the site, they have to hand carry all of the rebar down into the basement. They're using ASTM A615 grade 60 rebar. The pile of fishbone rebar delivered in the street, weighed eight tons!

Dennis and his crew from Jim Giancola Concrete continued their work laying out the rebar (that's Dennis on the left in the first picture). Because there's limited access to the site, they have to hand carry all of the rebar down into the basement. They're using ASTM A615 grade 60 rebar. The pile of fishbone rebar delivered in the street, weighed eight tons!Today they completed much of the bottom layer. When they're done with that layer, they'll construct another layer right above it. He expects we'll be pouring the concrete next Tuesday.

In case you're wondering what's inside the Baker Tank, the last picture shows you what it looks like. I sure wouldn't want to fall in there!

Tuesday, July 25, 2006

The plumber installed the sewer lines for the basement today. The second picture shows a close-up of the sewer ejector.

The plumber installed the sewer lines for the basement today. The second picture shows a close-up of the sewer ejector.The crew from Jim Giancola Concrete also started laying the rebar for the structural slab today.

Monday, July 24, 2006

These pictures were taken on Monday morning. On Friday, July 21, 2006, they had added a layer of Volclay Ultraseal over the entire mud slab. Here is a description of this water- proofing technology from the CETCO Building Materials Group website:

These pictures were taken on Monday morning. On Friday, July 21, 2006, they had added a layer of Volclay Ultraseal over the entire mud slab. Here is a description of this water- proofing technology from the CETCO Building Materials Group website:"Volclay Ultraseal is a technological advancement in below-grade waterproofing that combines natural sodium bentonite and a chemically resistant hydrophilic polymer to form a bentonite-polymer alloy (BPA). Ultraseal provides exceptional performance unmatched by other commercially available waterproofing systems. The key to Ultraseal’s exceptional performance is the unique bentonite-polymer interaction formed through a proprietary blending process. This process produces a homogeneous alloy with improved contaminant resistance, enhanced swelling properties, and a baseline permeability one magnitude better than natural sodium bentonite. Not only does Ultraseal have a lower permeability, it weighs 50% less than traditional bentonite products, making it easier to handle and install. The active, swelling properties of the bentonite-polymer alloy seals small concrete cracks and works under continuous and intermittent hydrostatic conditions."

Thursday, July 20, 2006

The mud slab was poured two days ago and is almost dry now. You can clearly see the indentations for the sewer lines. Along the right side and in the back right corner, you can also barely make out the indentations for the light wells.

The mud slab was poured two days ago and is almost dry now. You can clearly see the indentations for the sewer lines. Along the right side and in the back right corner, you can also barely make out the indentations for the light wells.On Monday, the plumber will come to lay the pipes. Then later next week, the steel (rebar) goes in, on top of the water protection layer. Brad hopes to pour the structural slab on next Friday.

Tuesday, July 18, 2006

Here is a picture of that concrete form that was cast by Ferma. They set it in place yesterday.

Here is a picture of that concrete form that was cast by Ferma. They set it in place yesterday.The first cement mixer arrived at about 10 AM this morning. That's a picture of Brad (on the left) talking to George.

They started pouring the 4" thick mud slab in the back left corner and worked their way to the right. Brad said he's bringing in 4 truckloads of cement at about 9 yards per truck. That's almost 1,000 cubic feet of cement.

Friday, July 14, 2006

Here are a series of pictures taken on Friday, July 14, 2006.

Here are a series of pictures taken on Friday, July 14, 2006.In the first picture, you can see all the gravel has been put down. You can also see the shoring that was done on the right-side of the property. The same was done on the left-side. The reason for this shoring is to prevent the excavated walls from caving in. Normally they would cut the walls at an angle like they did at the back (as seen in the left half of this picture). But they can't do that on the sides because the house is only a few feet from the property line. The large 4-foot diameter round sleeve buried in the ground (the black object at the bottom middle of the picture) is where the sewer ejector is supposed to go. It's the lowest point in the basment. Unfortunately it's filled with water.

The next three pictures show a few of the sump pumps. The first one is near the sewer ejector, in the front of the property. As you can see, the water is just gushing into the french drain. The next one is located in the back right of the property. And the last one in located in the back left of the property.

The last picture is a basement-level view. From here you can better see the trenches for the sewers in the basement.

Brad met with Dennis, Rob, and George from Waterproofing Associates at the job site today to discuss the de-watering issues. The plan is to drop Water Stopper into the sleeve to seal the bottom as much as possible and prevent more water from bubbling up into the sleeve. Waterproofing Associates also suggested using Water Stopper wherever we have small puddles of water, such as in the light wells. They seem very satisfied with the waterproofing technique our contractor is using.

In the meantime, Ferma is casting a concrete form. It will have a 36" outer diameter and a 27" inner diameter. Using a crane, they will place the concrete form into the sleeve where it will keep the water out, while the mud slab is poured. If all goes well, the concrete form will be in place on Monday, and the mud slab will be poured on Tuesday.

Wednesday, July 12, 2006

We met with Gary (our architect from Focal Point Design), Brad, and Chris (from Argonaut Window & Door) today to finalize the Andersen window order. There were only a few window changes and a bunch of minor updates. We're all on the same page now, so our windows are all set!

Tuesday, July 11, 2006

Today they started laying a bed of gravel on top of thick plastic. The gravel will serve as the base for the mud slab.

Today they started laying a bed of gravel on top of thick plastic. The gravel will serve as the base for the mud slab.In the third picture you can see the forms for one of the light wells.

In the last picture, you can see we still have de-watering issues where they had to dig trenches for the sewer lines. These trenches are several inches lower so that the sewer lines can slope (1/4" per foot) down to the sewer ejector. The sewer ejector will pump the sewer water out of the basement.

Thursday, July 6, 2006

Lea & Braze Engineering staked the foundation a couple of days ago. Dennis, the field foreman for Jim Giancola Concrete in Hollister, and his crew have started building the forms for the slab. The last picture is a better view of the large Baker tank. To give you an idea of it's size, those chain link fences are six feet tall.

Lea & Braze Engineering staked the foundation a couple of days ago. Dennis, the field foreman for Jim Giancola Concrete in Hollister, and his crew have started building the forms for the slab. The last picture is a better view of the large Baker tank. To give you an idea of it's size, those chain link fences are six feet tall. Speaking of fences, you've probably seen those red NATIONAL signs on fences (and port-a- potties) hundreds of times before. I never paid any attention to those signs, but National Construction Rentals is a huge company that rents all those things and more. We're also renting a temporary power pole from them.

Speaking of fences, you've probably seen those red NATIONAL signs on fences (and port-a- potties) hundreds of times before. I never paid any attention to those signs, but National Construction Rentals is a huge company that rents all those things and more. We're also renting a temporary power pole from them.

Subscribe to:

Posts (Atom)